Sakya Carbon has a own wheel assembly team.

At the beginning of the company's establishment, our wheel assembly was outsourced. But we find that customers often found problems with misaligned wheel centers, uneven or insufficient spoke tension after receiving the wheel assembly.

So starting from 2015, in order to provide better wheel quality, Sakya Carbon established our own wheel assembly team. All shipped wheel assemblies must undergo inspection by quality inspectors on the appearance, center, and spoke tension of the wheel assemblies. Only after passing the inspection can they be shipped.

The advantages are obvious:

1).When customers place orders, we can quickly ship and simplify the wheel weaving process. With wheel rims in stock, we can achieve same day shipment for customers.

2). We can accurately ensure that the shipped products will not have quality issues during assembly.

Anyway, Sakya Carbon, quality comes first.

-

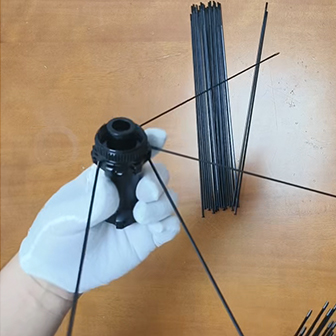

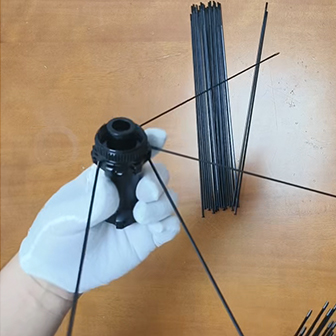

1.Preparing the spoke and hub assembly

First, prepare all the necessary components, including hubs, spokes, and rims. Check that all components are intact and that the spoke lengths are appropriate for the chosen rim.

-

2.Attach spokes to rim

Attach the other end of the spokes to the rim, using a professional tool to make sure each spoke passes correctly through the rim's spoke hole. This step requires careful attention to ensure the spokes are aligned correctly.

-

3.Precisely adjust spoke tension

Use a tensiometer and professional tools to make precise adjustments to the tension of each spoke. Make sure all spokes have even tension, this will directly affect the strength and durability of the wheel.

-

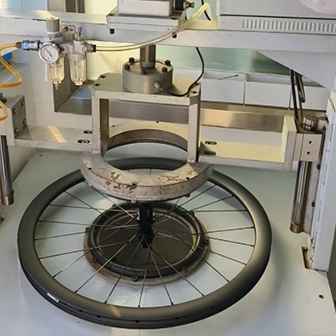

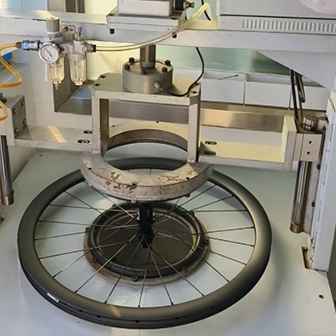

4.Initial wheel truing with professional equipment

Install the hub on a professional rim adjustment table and use the rim adjustment tool to make preliminary adjustments to the rim to ensure the roundness and symmetry of the rim. This is a critical step to ensure wheel quality.

-

5. Test rim centering

Mount the wheel on a truing stand, test and adjust to keep the rim perfectly centered (no left/right deviation) – a critical step for hub quality.

-

6.Final quality check

A final quality check is performed to ensure the rim's roundness, symmetry and spoke tension are all up to professional standards. This step ensures the performance and longevity of the wheel.